Limerick based researchers have helped to devise a new method to take impurities out of polluting gases using a sponge like material.

The scientists say the development could lead to reductions in harmful emissions, as well as a cut in energy use around the world.

The work was carried out by a team at the University of Limerick (UL) in collaboration with colleagues in other institutions outside the country.

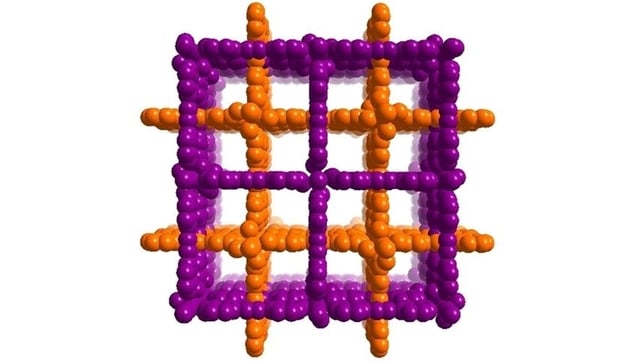

The researchers found that a sieve-like structure, SIFSIX-2-Cu-i, can act like a sponge, mopping up acetylene - a colourless gas made of carbon and hydrogen.

It has proven particularly useful during the making of ethylene - a gas that is commonly used in a huge variety of applications, including the ripening of fruit and the manufacture of plastics like polythene.

During the process of making ethylene, acetylene impurities must be removed from the product.

Large amounts of energy are required to filter out such impurities, usually through processes like distillation.

Other forms of purification have been tried, like separating molecules according to their size, structure or properties.

But they don’t work well in removing acetylene.

The UL team, led by Prof Michael Zaworotko and Dr Kai-Jie Chen, initially probed whether materials called Hybrid Ultramicroporous or HUMs - tiny atomic-sized sieves - could be useful for filtering out impurities.

But the researchers subsequently discovered that HUMs like SIFSIX-2-Cu-i actually act more like sponges.

Collaboration and pooling of knowledge with other scientists in institutions outside Ireland led to the development of a material capable of soaking up acetylene during the production of ethylene.

The team says their new invention offers a more environmentally friendly, cost effective way to purify ethylene, the most intensively produced organic chemical in the world.

The same approaches could also work for purification of other substances like carbon and water, they say.

Commodity purification currently accounts for between 10-15 per cent of the world’s energy consumption.

As a result, if the processes currently used were to be replaced with more energy efficient technologies like these sponges, the US alone could save 100 million tonnes of carbon dioxide emissions and US$4 billion in energy costs annually, the team estimates.

The research is published in the current edition of the respected international journal, Science.